Beginner’s Guide to Gauge Widening for Miniature Railways

- Dec 7, 2025

- 5 min read

A friendly introduction to what gauge widening is, why miniature railways use it, and how the PNP Railways track system makes it simple to build smooth-running curves.

Gauge widening might sound like a specialist railway engineering term, but the principle is simple: trains run more smoothly through curves when the rails are set slightly further apart.

On miniature railways, especially 5" and 7¼" gauge, locomotives often have limited side-play and relatively rigid wheelbases. On tight curves, this can lead to wheels binding against the rails, increased friction, wear on both the rails and the rolling stock, and, in extreme cases, derailments.

The PNP Railways track system is designed with gauge widening in mind. Our plastic sleepers and matching chair designs allow you to build in precise widening simply by rotating the chairs as you assemble the track — no shims, packing pieces or redrilling required.

If you are new to the subject, the questions and answers below will walk you through the basics, before the glossary at the end explains some of the technical terms in plain language.

Quick facts

Gauge widening is applied only to curves, not to straight track.

Typical amounts are +1/32" or +1/16", depending on curve radius.

With PNP plastic sleepers, widening is built in via the chair orientation.

Automatic gauge widening does not work with wooden or recycled plastic sleepers.

Gauge Widening for Miniature Railways - Q&A

Q1. What is gauge widening?

Gauge widening is a small, intentional increase in the distance between the two rails when laying track through a curve. By opening the gauge slightly, the wheelsets have a little more freedom to follow the curve without binding against the rail.

Q2. Why do miniature railways need gauge widening?

Many miniature locomotives and passenger carriages have relatively stiff frames and limited side-play in their wheelsets. On tight curves, this can cause the wheel flanges to rub hard on the rail, increasing friction and wear and raising the risk of wheel climb. A small amount of gauge widening reduces these forces, resulting in smoother, more reliable running.

Q3. How much widening is normally used?

In typical miniature railway practice, builders often use around +1/32" for medium curves and +1/16" for tighter radii. The PNP Railways track system is engineered around these increments, so they can be achieved simply by rotating the chairs on our plastic sleepers.

Q4. How does the PNP system build gauge widening into the track?

All PNP chairs designed for use with our plastic sleepers — including Screw Fit, Clip Fit, and Bar Rail Chairs — sit on a spacer with an offset locating spigot. Depending on which way the chairs are oriented on the sleeper, the rail position changes slightly.

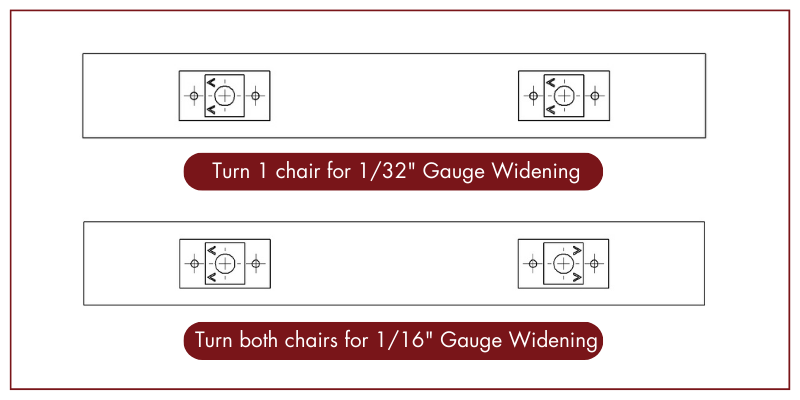

With both chairs in their standard orientation, you have a normal gauge. Turning one chair 180° provides approximately +1/32" widening, and turning both provides approximately +1/16" widening.

Q5. Does automatic gauge widening work with all sleeper types?

No. The automatic widening feature relies on the moulded housings and locating sockets in PNP plastic sleepers. Chairs supplied for wooden or recycled-plastic sleepers have a flat underside and round fixing holes, without an offset spigot. They secure the rail in place, but they do not provide automatic gauge widening. This would have to be done manually.

Q6. Which rail profiles can be used with automatic gauge widening?

When used with PNP plastic sleepers, automatic gauge widening works with all three rail profiles supported by our standard scale system: 16 mm flat-bottom aluminium rail, 21 mm (2 lb/yard) flat-bottom aluminium rail, and 10 mm × 20 mm bar rail. Each rail type has its own matching chair that fits the sleeper and works with the offset spigot system.

Q7. Where should gauge widening start and end on a curve?

For smooth running, it is best to introduce gauge widening gradually. A common approach is to begin widening two or three sleepers before the curve, maintain the widening through the curve itself, and then return to standard gauge over the next two or three sleepers after the curve. This avoids sudden changes that can be felt by the wheels.

Q8. How can I check that my gauge widening is correct?

Many builders use a stepped track gauge with settings for nominal gauge, +1/32", and +1/16". Others prefer a more practical test, such as pushing a free-running bogie or a rigid wheelbase test wagon through the curve and feeling for tight spots. A slow-speed test run with a locomotive is often the final check.

Q9. Does gauge widening help reduce wear on aluminium rail?

Yes. By reducing flange pressure on curves, gauge widening can significantly reduce flange marks and general wear on aluminium rail, particularly on tight-radius sections and heavily used club or passenger-hauling lines.

Q10. Is gauge widening always necessary?

Not always. On large-radius curves, many miniature railways operate successfully at standard gauge without widening. The tighter the radius and the longer or stiffer the wheelbase, the more beneficial gauge widening becomes. For gentle curves, good alignment and consistent sleeper spacing may be sufficient on their own.

Glossary of Useful Terms

A quick reference for some of the technical language used in track building.

GaugeThe distance between the inside faces of the two rails. In standard gauge full-size railways this is 4 ft 8½ in; in miniature railways it is the nominal track width for 3½", 5" or 7¼" gauge. | Gauge wideningA small, deliberate increase in the gauge on curves to help wheels pass through without binding or excessive flange pressure. | SleeperA transverse beam that supports the rails and holds them to gauge. PNP offers plastic sleepers with moulded detail and a hollow ribbed underside to allow ballast to key in. |

ChairThe fitting that secures the rail to the sleeper. Different chair designs are used for different rail profiles and sleeper materials. | SpigotA projecting peg on the underside of certain PNP chairs and spacers that locates into the plastic sleeper. Its offset position allows automatic gauge widening when the chair is rotated. | FlangeThe inner lip on a railway wheel that keeps it running on the rail. The flange bears against the inside of the rail on curves. |

Flange rubbingContinuous contact between the wheel flange and the rail, usually on a tight curve. It increases friction and wear and may be a sign that gauge widening would be beneficial. | Wheel climbA type of derailment where the wheel flange rides up and over the rail instead of staying inside it, often caused by high flange forces on curves or irregularities in the track. | Rail profileThe cross-sectional shape of the rail, such as a flat-bottom aluminium rail or a rectangular bar rail. PNP standard scale track supports 16 mm, 21 mm and 10 × 20 mm bar rail. |

Bar railSimple rectangular section rail, such as 10 × 20 mm black bar. Strong and easy to weld, but less prototypical in appearance than a flat-bottom rail. | FishplateA metal plate used in pairs to join two rail ends together with bolts, maintaining alignment and electrical continuity where required. | WheelbaseThe distance between axles on a locomotive or wagon. Longer or rigid wheelbases are more sensitive to tight curves and poor gauge. |

BogieA small wheeled frame or truck that can pivot beneath a locomotive or vehicle. Bogies help longer vehicles negotiate curves more easily. | Curve radiusThe size of a curve, measured as the radius of the circle it forms. A smaller radius means a tighter curve and usually a greater need for gauge widening. |

This guide is intended as a general introduction. For specific advice on your own railway, including recommended sleeper types, rail profiles and chair combinations, please get in touch with the PNP Railways team.

Comments